Aerial Pole Design

Comprehensive pole inspection, structural analysis, and engineered make-ready designs stamped by a licensed P.Eng.

Our Aerial Pole Design Services

- Engineering review and pole inspection: Identify structural, safety, and make-ready requirements through field inspection and reporting.

- Hazard assessment & defect mitigation: Assess hazard conditions and unflagged defects with engineered mitigation solutions.

- Technical drawing review: Confirm attachment feasibility and compliance with utility standards and client requirements.

- Pole loading & structural analysis: SpidaCalc analyses performed in accordance with CSA and utility design standards.

- Validation of pole condition: Review inspection reports to confirm structural adequacy or recommend remediation.

- Engineering adjustments: Modify designs to meet clearance, loading, and safety requirements.

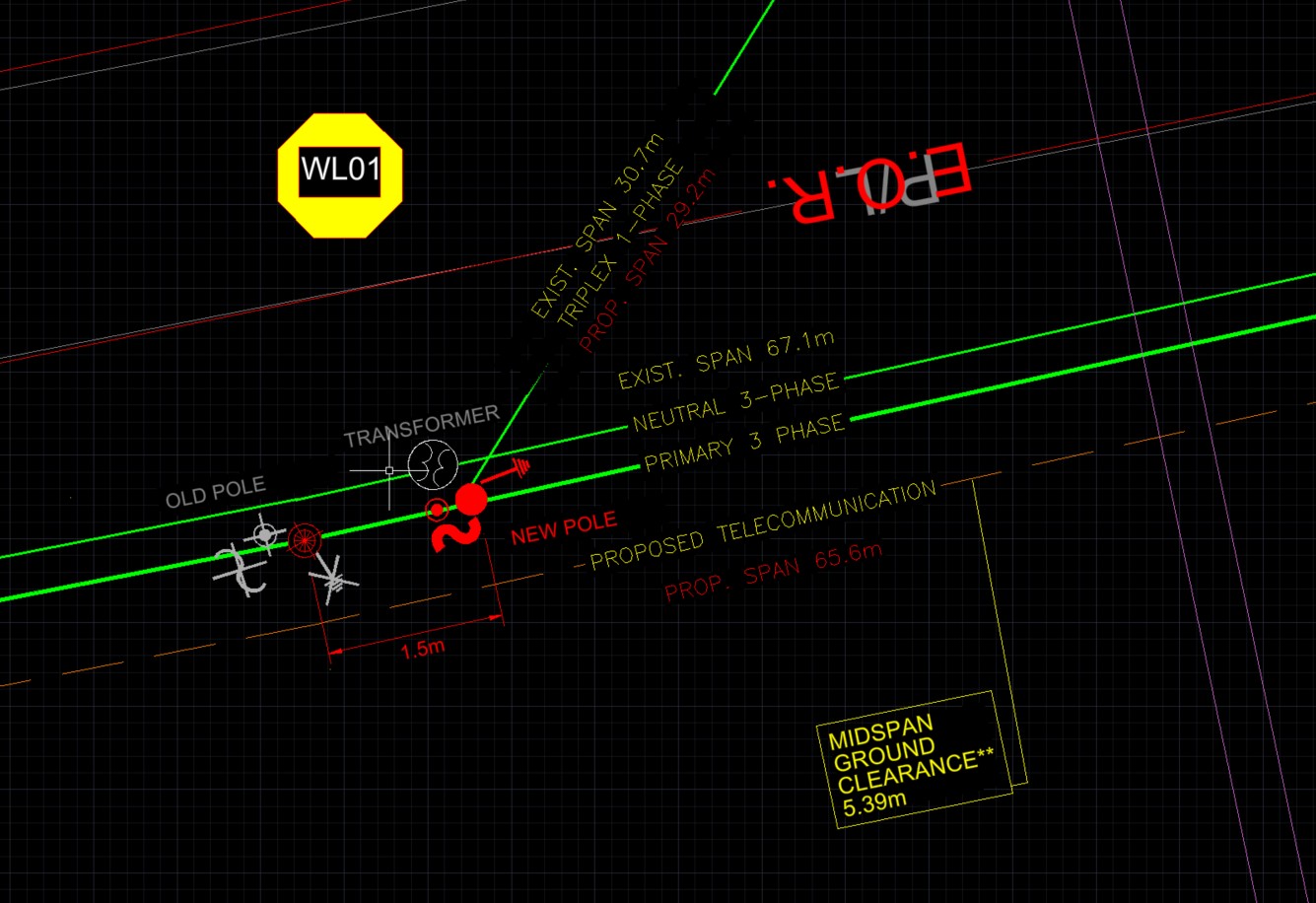

- GIS & CAD integration: Integrate GIS datasets and CAD records to build accurate pole models and alignment data.

- Engineered drawings & deliverables: Prepare AutoCAD pole and make-ready drawings, stamped and sealed by a licensed P.Eng.

- Independent engineering review & QA/QC: Provide an independent peer review, quality assurance and quality control prior to issue for construction.

Pole Inspection & Assessment

Our comprehensive inspection process identifies structural, safety, and make-ready requirements through detailed field analysis. We assess pole condition, capture critical measurements, and document all findings for engineering review and design planning.

- Structural condition assessment

- Hazard identification and documentation

- GIS and geolocation data capture

- Attachment feasibility evaluation

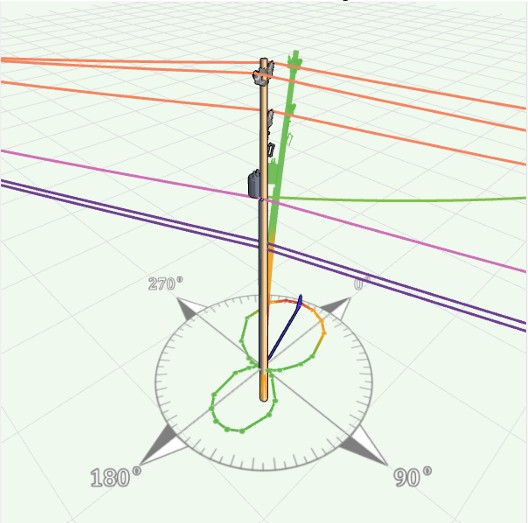

SpidaCalc Structural Analysis

We perform pole loading and structural analysis using SpidaCalc, following CSA standards and utility-specific design guidelines. Our analysis includes wind and ice loading cases, attachment configurations, and detailed loading summaries for each pole structure.

- CSA-compliant loading analysis

- Wind and ice load calculations

- Attachment configuration review

- Detailed design summary reports

Licensed Engineering Deliverables

All engineered drawings are produced in AutoCAD and stamped and sealed by a licensed Professional Engineer (P.Eng). We provide comprehensive make-ready designs, GIS integration, and independent engineering review to ensure quality and compliance.

- P.Eng-stamped AutoCAD drawings

- Make-ready design optimization

- GIS-integrated CAD models

- Independent quality review and sign-off

Deliverables

- Pole inspection report with condition grading

- SpidaCalc loading reports and summary tables

- Engineered make-ready drawings (AutoCAD, P.Eng-stamped)

- GIS-integrated CAD models and attribute tables

- Independent engineering review report

Workflow

- Field inspection & data collection

- Technical review of attachments and clearances

- SpidaCalc structural analysis and design adjustments

- Drafting of AutoCAD pole and make-ready drawings

- QA/QC, P.Eng stamp and final deliverables